Defective control valves mixing water – no proper cooling or heating

Full Service Sheraton Suites - Plantation, FL

Sheraton Suites, a South Florida landmark, selected AirRevive to refurbish its 264 IEC guest room vertical fan coil units during its multi-million dollar renovation. The units were manufactured in 1989.

Fan Coil Units Manufacturer: International Environmental (IEC) Models#: TURBO4D5, TURBO6D5

Project Scope of Work

Guest room vertical fan coil unit refurbishment and valve replacement.

Challenge: The airflow was below design specifications due to impacted coils. The control valves were leaking by which was causing simultaneous heating and cooling, thus wasting energy and inhibiting the unit’s ability to cool and heat as designed. Coil condition was negatively impacting indoor air quality because organic material and dirt were stuck in the coil core. Airflow on high fan was insufficient for proper cooling. Insulation was torn and with fiber floating around return and supply areas. Fiber was stuck in coils. Electric heaters were dusty and dirty inhibiting proper heating and causing a foul smell. The motor was dirty and stuck to the blower wheel in some units. The blower assembly and wheel were dirty. The pans were rusting and corroding causing the drain line to clog. The project’s goal was to bring the units back to efficient operation.

- Coil temperature average was 60.2℉.

- 88% of the unit’s coil temperature was above 54℉.

- Supply temperature average was 62.3℉.

- 86% of the unit’s supply temperature was above 60℉.

- The airflow was below the manufacturer’s design curve of 810 FPM to 990 FPM averaging 670 FPM.

- Some PSC motors at the Sound decibels were measured at an average 60.79 dB with over half of the units above the industry acceptable limit of 60 dB.

Solution: The refurbishment solution included: Coil rejuvenation from the front to back to deep in the core; Rejuvenating the coils increased airflow and enhanced heat transfer; Applying epoxy to the condensate pan; Cleaning and disinfecting the blower assembly and wheel; Clearing out, cleaning and disinfecting the drain line; Replacing fiber insulation with anti-microbial fiber-free foam insulation; Disinfecting and deodorizing the electric heaters to eliminate the foul smell; and Replacing control valves to eliminate simultaneous cooling and heating.

Results

Coil temperature dropped by 10.5℉ from an average of 60.2℉ to 49.7℉.

Supply temperature dropped by 5.2℉ from an average of 62.3℉ to 57.1℉.

Airflow raised by 27% from an average of 670 FPM to 910 FPM.

Sound decibels reduced by 7% from an average of 60.79dB to 56.65dB.

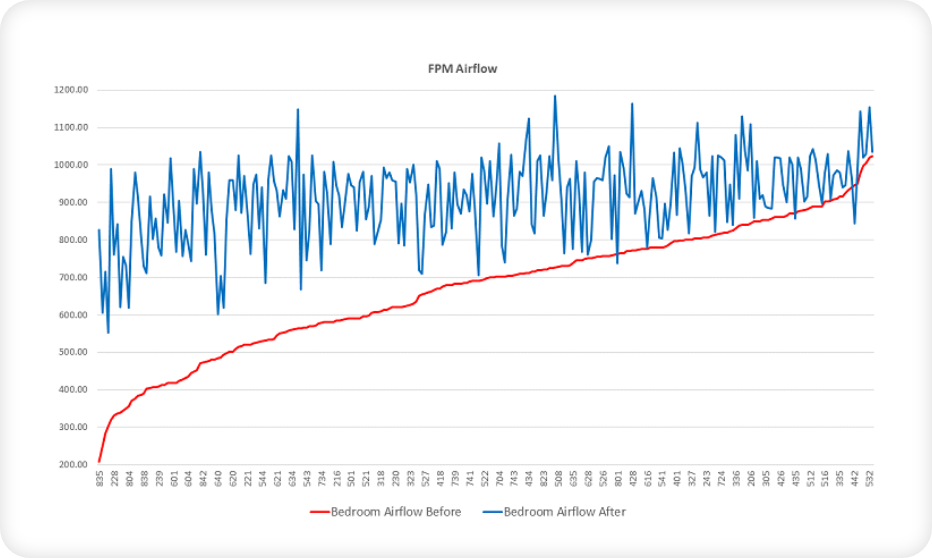

Before & After Airflow Data

The graph below displays before and after airflow on high fan setting. The red line from left to right demonstrates the airflow before service from low to high ranged from 210 FPM to 1010 FPM. The blue line demonstrates the airflow after service within the manufacturer’s design target of 810 FPM to 990 FPM. The horizontal axis represents the room numbers.

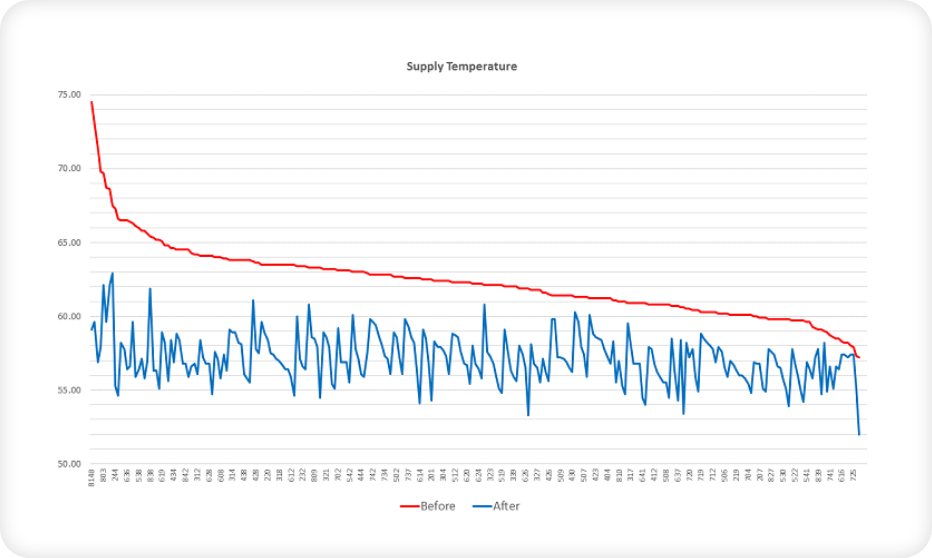

Before & After Supply Temperature Data

The graph below displays before and after supply temperature. The red line from left to right demonstrates the supply temperature before service from high to low ranged from 74 degrees to 57 degrees averaging 62.3 degrees. The blue line demonstrates the supply temperature after service averages 57.1 degrees. The horizontal axis represents the room numbers.

Ready to Refurbish Your Fan Coil Units without losing revenue?

Our experts will assess your property and provide a detailed improvement plan.