Washington Dulles Airport Marriott

Offering high-tech amenities, outstanding service and a convenient central location, Washington Dulles Airport Marriott is ideal for business and leisure travelers alike. The hotel is located less than a mile away from Dulles International Airport.

The hotel engaged AirRevive to refurbish and retrofit 167 guest room fan coil units manufactured in 1984.

Fan Coil Units Manufacturer: Unilux

Models#: SC600

Project Scope of Work: Guest room vertical fan coil unit refurbishment and EC motor retrofit.

Challenge: Impacted coils was causing low to no airflow. The goal was to bring the existing fan coil units back to “as-new” or better operating efficiency; and complete the project without interrupting the hotel operations and its consistent 96%+ occupancy.

- Coil temperature averaged 51.5℉.

- 56% of the unit’s coil temperature was above 50℉.

- Sound decibels across all units averaged 64.6 dB (60 decibels is the highest industry accepted level).

- 450 CFM airflow design on high setting averaged 234 CFM and the 250 CFM airflow design on low setting averaged 178 CFM.

- 35% of the units had no airflow on low setting.

- 15% of the units had no airflow on high setting.

- 65% of the units had airflow below manufacturer’s specifications – 250 CFM on low setting.

- 90% of the units had airflow below manufacturer’s specifications – 450 CFM on high setting.

Solution: The refurbishment service included the following:

- Refurbish and apply epoxy to the condensate pan;

- Clean and disinfect the blower assembly and wheel;

- Clear out, clean and disinfect the drain line;

- Replace fiber insulation with anti-microbial fiber-free foam insulation; and

- Coil rejuvenation from the front to back to deep in the core resulting in lowered coil temperature and unrestricted airflow preparing the coils for the EC motor retrofit.

The EC motor retrofit solution included customizing the shaft length to fit the existing blower and wheel; customizing the bracket to mount the EC motor on the existing blower housing; programming the EC motor to supply airflow consistent with the unit specification, room area and building nuances; installing the motor and controller; and wiring the motors to the thermostat for proper functioning.

Results

- Coil temperature dropped by 4.1 degrees from an average of 51.4℉. to 47.3℉.

- 73% of coil temperatures at or below 49.9 degrees.

- The average sound decibels decreased by 10% from an average of 64.6 dB to 58.8 dB.

- The 450 CFM design units’ airflow on high setting averaged 458 CFM.

- The 250 CFM design units’ airflow on low setting averaged 254 CFM.

- Guest rooms cool within minutes and maintain temperature set point.

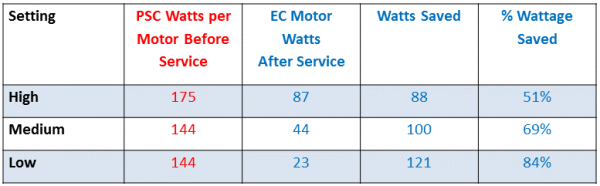

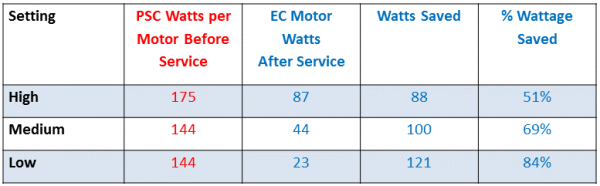

- The re-commissioned units reduced wattage by 84 percent on low, 69 percent on medium and 51 percent on high setting.

Energy Savings

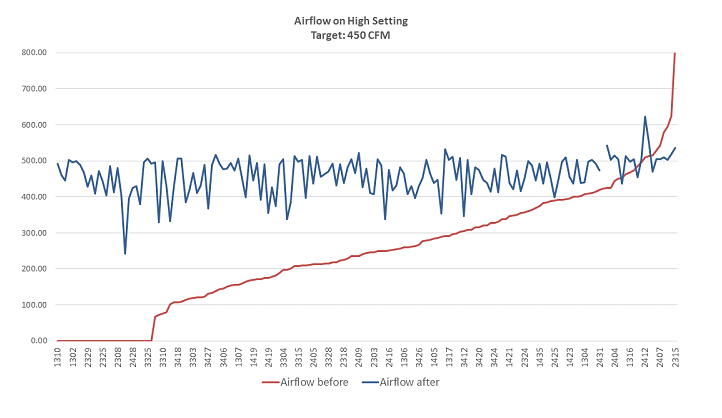

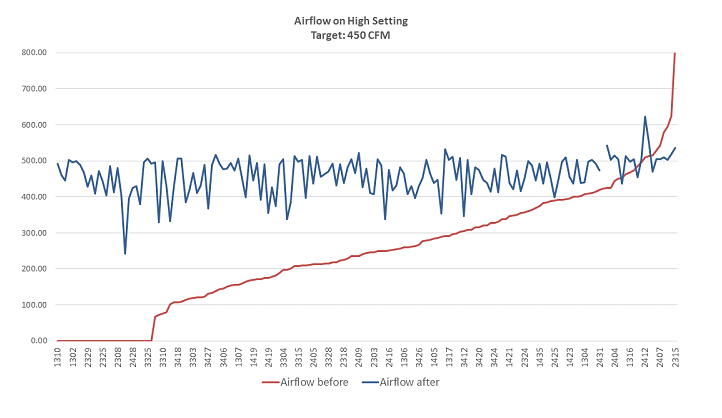

Before & After Airflow Data

The graphs below display the before and after airflow on high and low fan setting. The red lines from left to right demonstrate the airflow before service from low to high ranged from 0 degrees to 800 degrees on the 450 CFM airflow design and from 0 to 500 CFM on the 250 CFM airflow design. The blue line demonstrates the airflow after service is within the manufacturer’s design curve. The horizontal axis represents the room numbers.

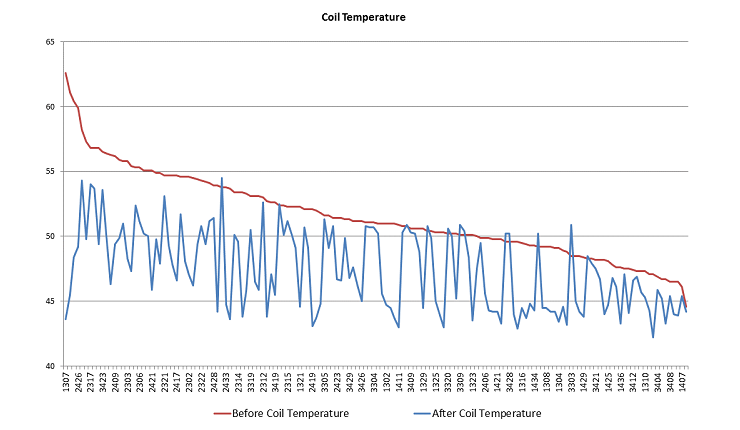

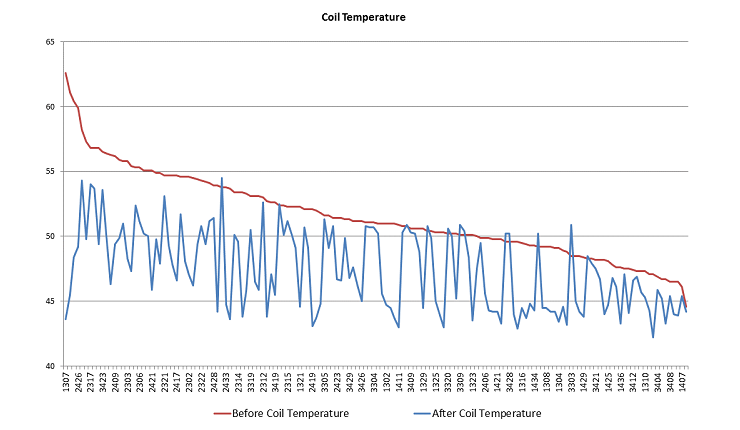

Before & After Coil Temperature Data

The graph below displays before and after coil temperature. The red line from left to right demonstrates the coil temperature before service from high to low ranged from 63 degrees to 44 degrees. The blue line demonstrates the coil temperature after service averaged 47.3 degrees. The horizontal axis represents the room numbers.