Houston Marriott Medical Center

Located in the heart of the internationally recognized Texas Medical Center, the Houston Marriott Medical Center Hotel is the ultimate destination for guests seeking a community of healing, learning and discovery.

The property engaged AirRevive to refurbish, re-commission and repair defective installation on 452 guest room vertical fan coil units that were manufactured in 1983.

Fan Coil Units Manufacturer: Lanco

Models#: LHO4-W4-B31, HLO6-W4-B31, ERO4-W4-31, ERO6-W4-31

Project Scope of Work: Guest room vertical fan coil unit refurbishment, structural repair and EC motor retrofit.

Challenges: Lower the coil and supply temperature by rejuvenating or replacing coils as needed and to bring airflow back to each unit’s manufacturer design specification. During the site survey, AirRevive found there was a gap between the fan coil unit cabinet and the guest room wall. This gap was causing return air to not draw across the coil completely and mix with the supply without being conditioned. The result was evident in the supply temperatures which were in the 60’s even though the coil was performing as designed.

- Coil temperature averaged 58.71℉.

- Supply temperature averaged 63.4℉.

- Airflow significantly higher than design specification. Airflow passing across the coil too quickly to dehumidify, cool, and heat as designed.

- 60% of the unit’s airflow was above the manufacturer’s specification curve.

- 24% of the unit’s airflow was below the manufacturer’s specification curve.

- Sound decibels averaged 62.76dB which is above the industry acceptable sound limit of 60dB.

Solution: AirRevive implemented a custom solution for the gap challenge by closing the gap and assuring all return air is drawn across the coil and not mixed with supply air. AirRevive also closed the hole in the bottom of the unit so that cabinet is fully insulated. AirRevive rejuvenated the coils and when needed, replaced them with custom made coils. To reduce FCU fan motor energy consumption, AirRevive retrofit the PSC motors with EC motors. The units were re-commissioned so that airflow is aligned with manufacturer’s design specifications and heat transfer is like new.

Results

- The coil rejuvenation achieved the project goals.

- Coil temperature dropped by 10.68℉ from an average of 58.71℉ to 48.03℉.

- The majority of coil temperatures were below 53 ℉.

- Supply temperature dropped by 9.9℉ from an average of 64℉ to 53.5.℉

- 410 CFM, 420 CFM and 530 CFM units’ high fan airflow were all within the manufacturer’s design curve.

- The EC motor resulted in a reduction in fan coil energy by up to 73%.

- Sound decibels dropped by 11.25 dB or 17.74% decrease from an average of 62.76 dB to 51.51 dB.

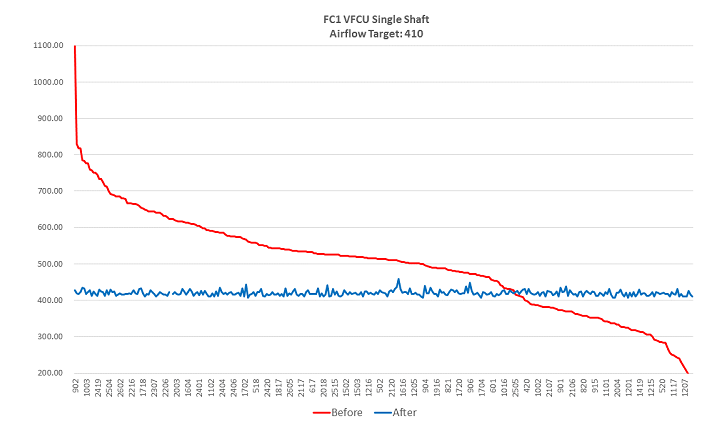

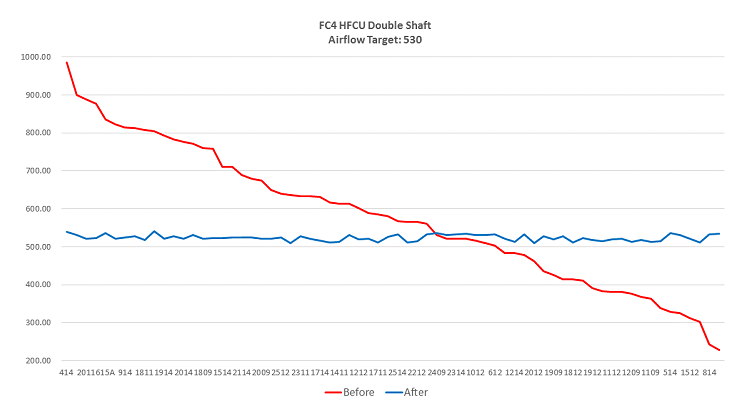

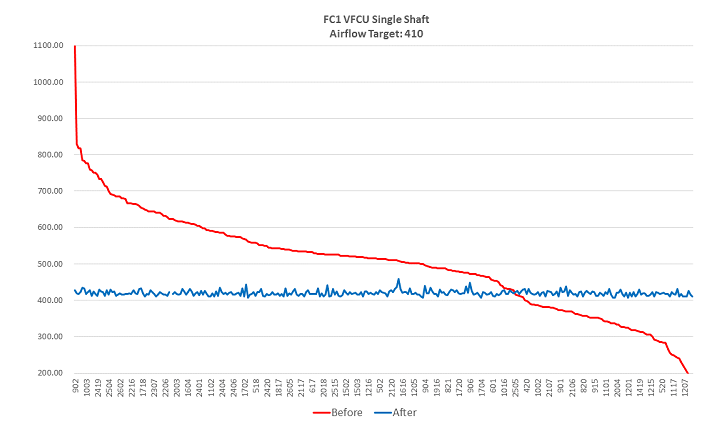

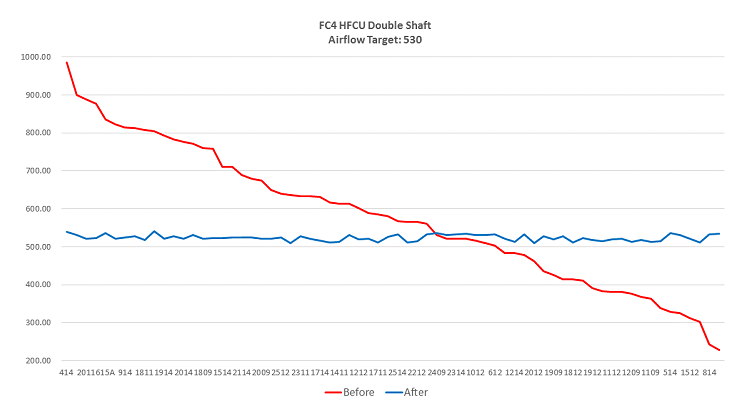

Before & After Airflow Data

The graphs below display the three unit types’ before and after airflow on high fan setting. The red line from left to right displays the airflow before service from high to low. The blue line demonstrates the airflow after service is within the manufacturer’s design curve. The horizontal axis represents the room numbers.

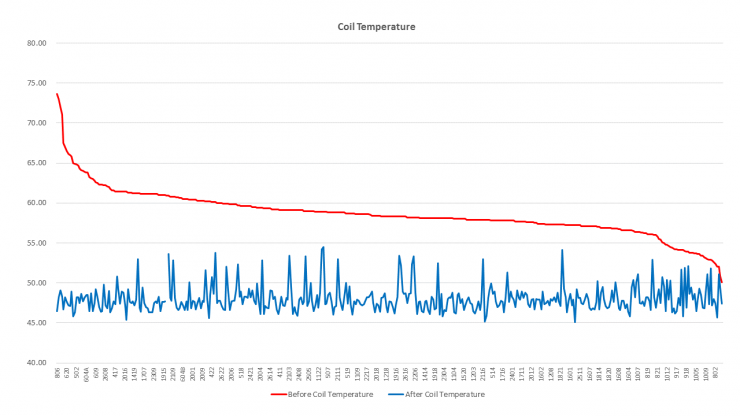

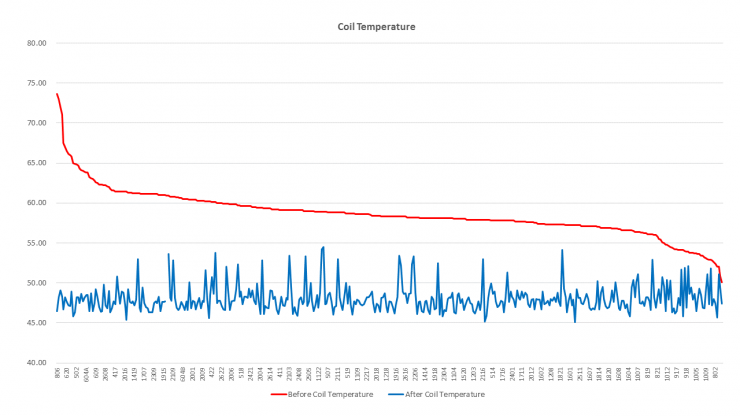

Before & After Coil Temperature

The graph below shows coil temperature sorted from high to low before coil rejuvenation. The red line demonstrates that before coil rejuvenation the coil temperature ranged from 73.6℉ to 50.1℉. The blue line demonstrates that the refurbishment and coil rejuvenation reduced the coil temperature to below 53℉ on over 95% of the units. The average coil temperature dropped to 48℉.

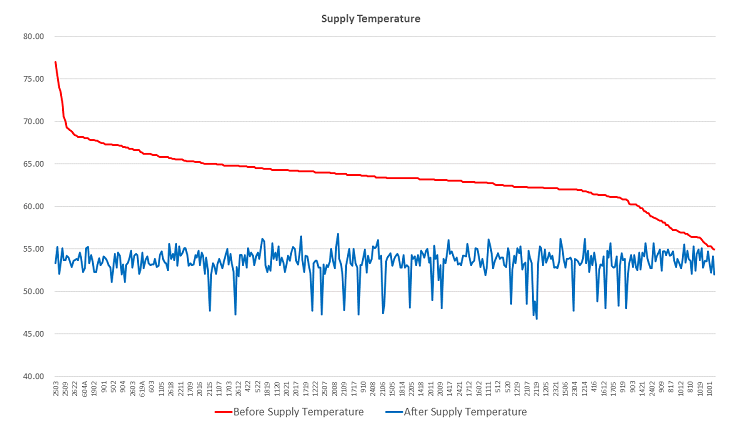

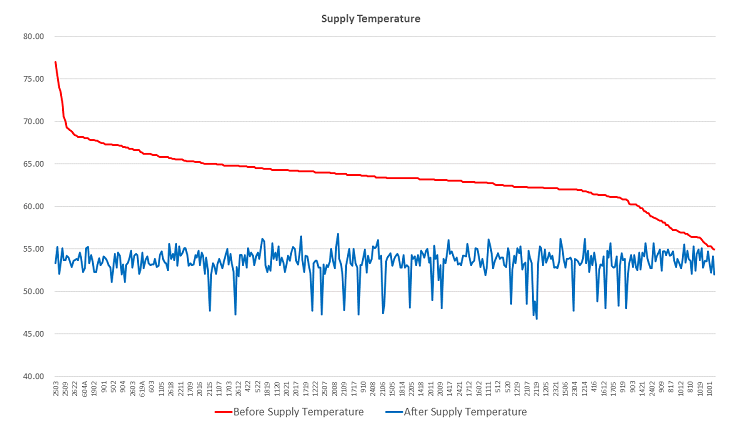

Before & After Supply Temperature

The graph below shows supply temperature sorted from high to low before coil rejuvenation. The red line demonstrates that before coil rejuvenation the supply temperature ranged from 77℉ to 55℉. The blue line demonstrates that after coil rejuvenation the supply temperature fell below 56℉ on 99% of the units. The average supply temperature after refurbishment and coil rejuvenation was 53.5℉.