CUSTOMER: Full Service Marriott

LOCATION: Little Rock, AR

INDUSTRY: Hospitality

AIRREVIVE SERVICE: Fan coil unit refurbishment

FAN COIL UNITS: 1980 Whalen Fan Coil Units

CUSTOMER: Full Service Marriott

LOCATION: Little Rock, AR

INDUSTRY: Hospitality

AIRREVIVE SERVICE: Fan coil unit refurbishment

FAN COIL UNITS: 1980 Whalen Fan Coil Units

Marriott engaged AirRevive to refurbish the guest room’s Whalen fan coil units after the property’s $16 million dollar renovation in 2014. The renovation included upgrading the guest rooms to Marriott’s new design. The only former asset remaining was the 35-year old Whalen fan coil units.

PROJECT GOALS

PROJECT SCOPE: COIL REJUVENATION & CABINET REFURBISHMENT

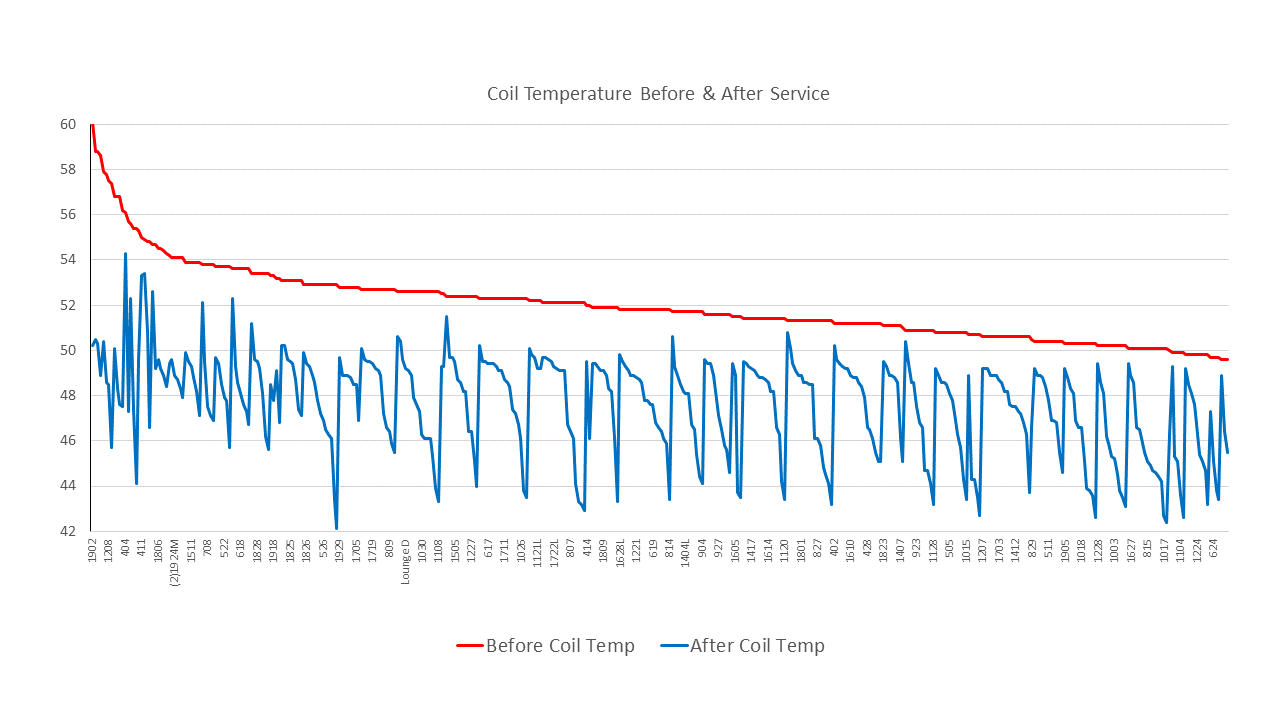

Coil Temperature Before and After Service

Summary: Coil temperature dropped by an average 4℉ from 51.6℉ to 47.4℉.

The graph below shows coil temperature sorted from high to low before coil rejuvenation.

The red line shows that before the coils were rejuvenated the coil temperature ranged from 60℉ to 50℉. The average coil temperature was 51.6℉. The coil temperature was above 50℉ on 85% of the units.

The blue line shows that after the coils were rejuvenated the coil discharge temperature for 98% of the units is below 50℉. The average coil temperature after service is 47.4℉.

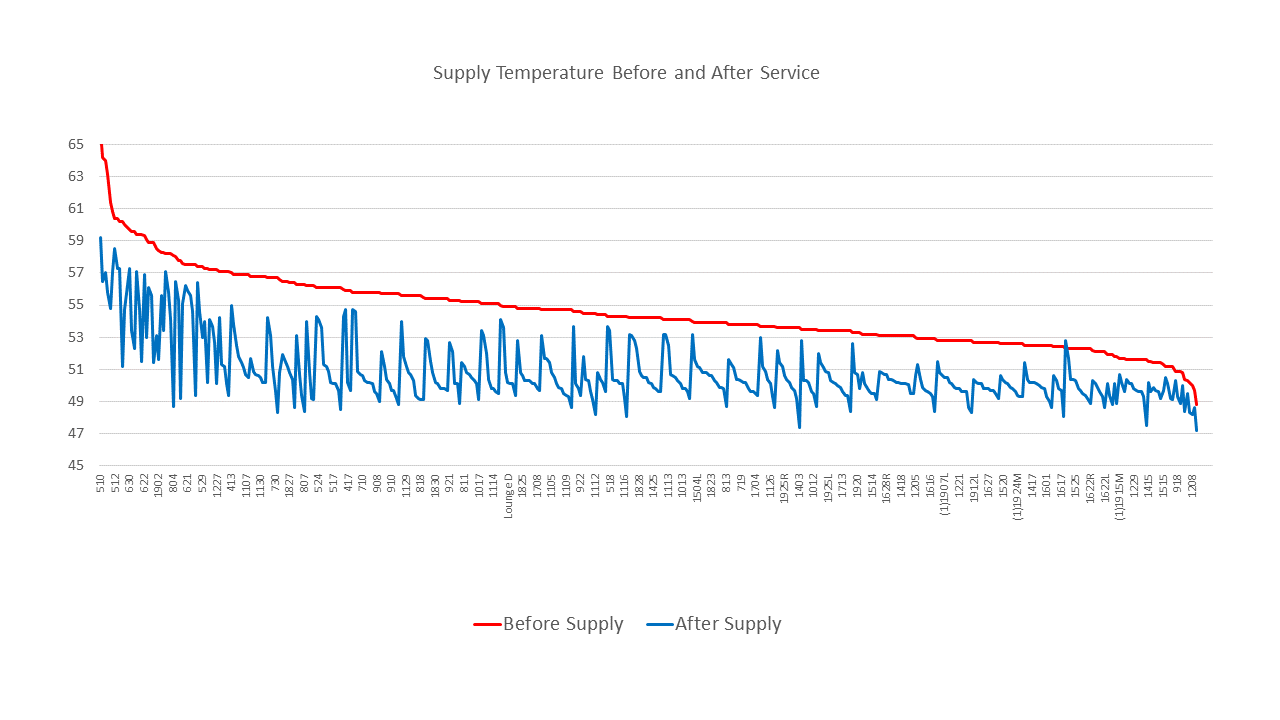

Supply Temperature Before and After Service

Summary: Supply temperature dropped by an average 4℉ from 54.5℉ to 50.8℉.

The graph below shows supply temperature sorted from high to low before coil rejuvenation.

The red line shows that before the coils were rejuvenated the supply temperature ranged from 65.8℉ to 48.8℉. The average supply temperature was 54.5℉. The supply temperature was above 52℉ on 90% of the units.

The blue line shows that after the coils were rejuvenated the supply temperature for the majority of the units fell below 51℉. The average supply temperature after service was 50.8℉.

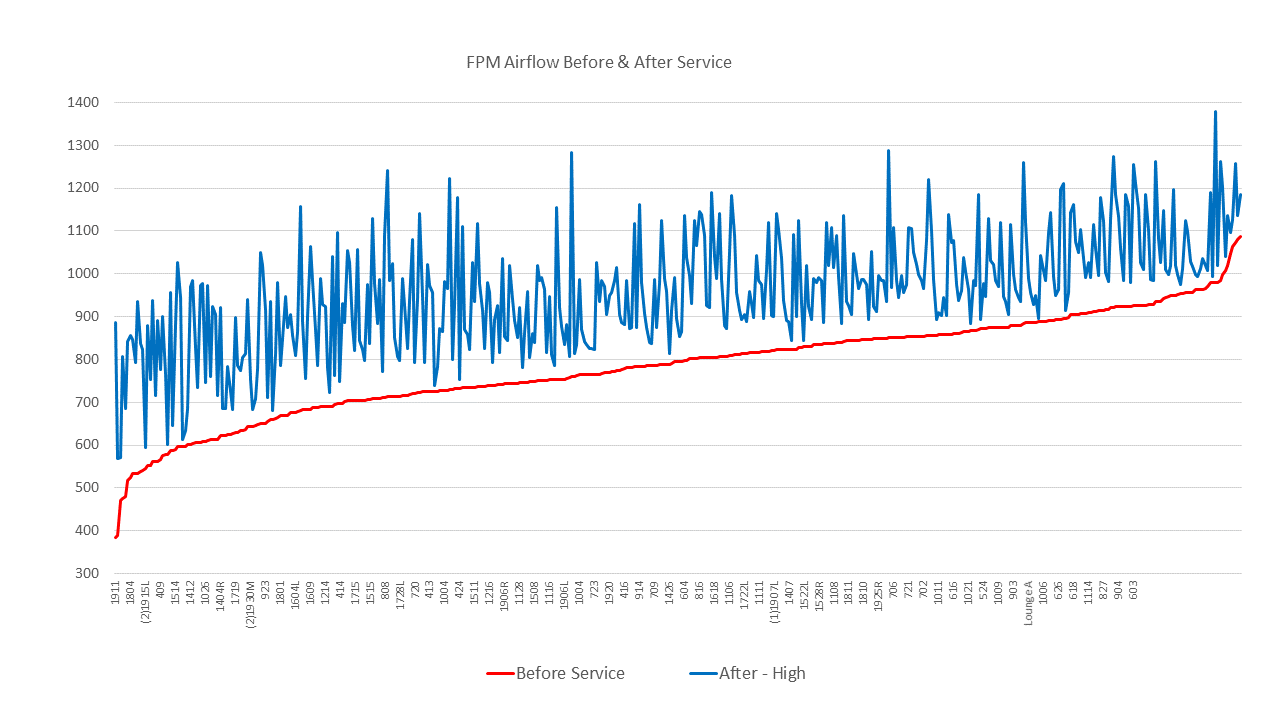

Airflow before and after service on low setting

Summary: Airflow increased by an average 22% from 785 FPM to 985 FPM.

The graph below is high fan airflow measured in FPM sorted from low to high before the coil rejuvenation.

The red line shows that before service the high fan airflow ranged from 385 FPM to 1085 FPM. Average airflow was 785 FPM.

The blue line shows that after service the high fan airflow ranged from 569 FPM to 1400 FPM.

Overall the coil rejuvenation increased the airflow by an average 22% from before 785 FPM to after 985 FPM

RESULTS SUMMARY

FACILITY BENEFITS

The project resulted in the fan coil units performing more efficiently. The benefits to the facility are the following: