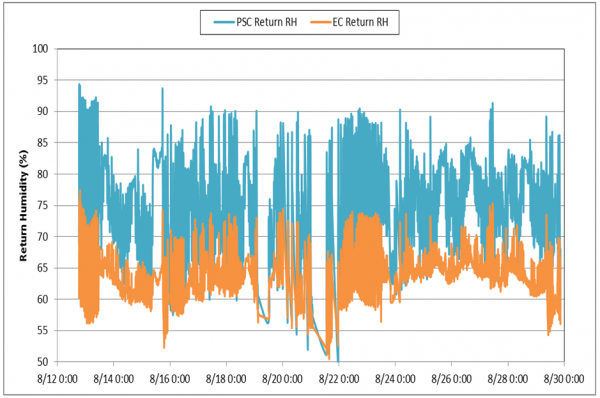

The unit retrofit with an EC motor reduced guest room relative humidity by up to 25%

Guest Room Relative Humidity

Relative humidity below 66% signifies dry air.

The unit retrofit with an EC motor maintained guest room relative humidity at or below 65%.

The PSC motor guest room humidity ranged daily between 65% – 90%. This allowed for high humidity time periods.

The data demonstrates that the EC motor maintained guest room relative humidity within a narrow band while the PSC motor produced relative humidity that fluctuated widely.

These results are to be expected because the EC motor airflow is programmed to the manufacturer’s design specifications. When the air moves across the coil at the correct speed the coil evaporates humidity as designed. The PSC motor relative humidity fluctuated widely because the motor on high speed over-blows, which does not allow for water to be evaporated from the air.